Geomembrane Hdpe Geomembrane 1mm 1.5mm Geomembrane Pool For Fish Pond

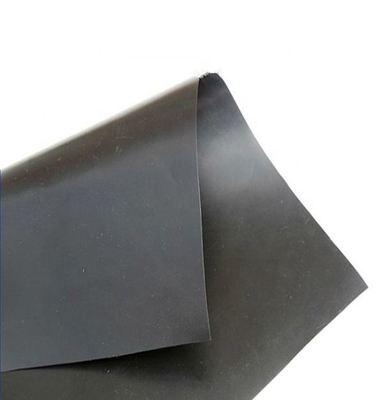

Basic Details Geomembrane; pond liner

1. Main Thickness: 0.1mm,0.2mm,0.3mm,0.5mm, 0.75mm,1.0mm,1.5mm,2.0mm,3.0mm,4.0mm,5.0mm

2. Main Width: 4m, 5m, 5.8m, 6.0m, 7m, 8m,10m

3. Main Length:50m/100m

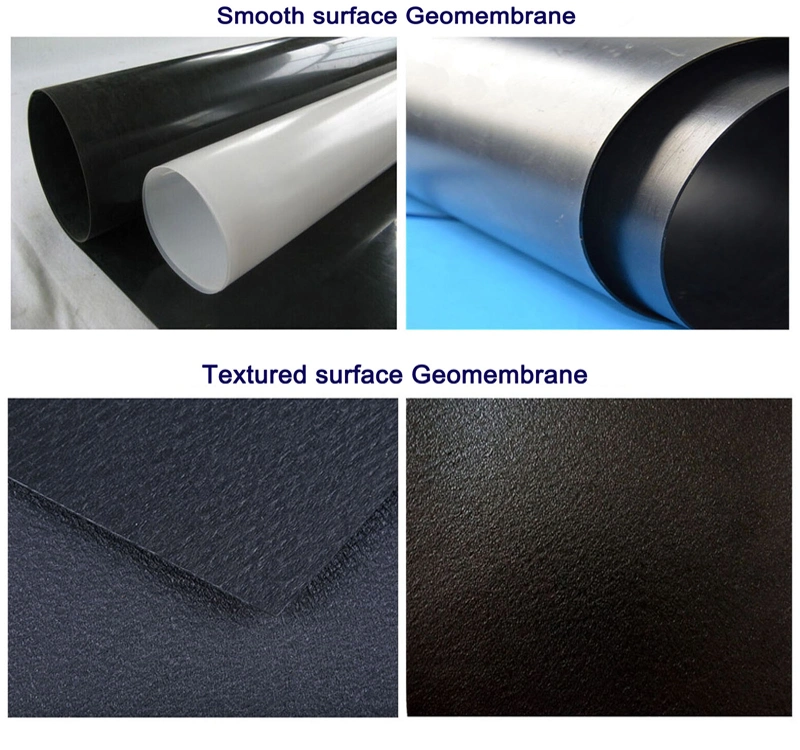

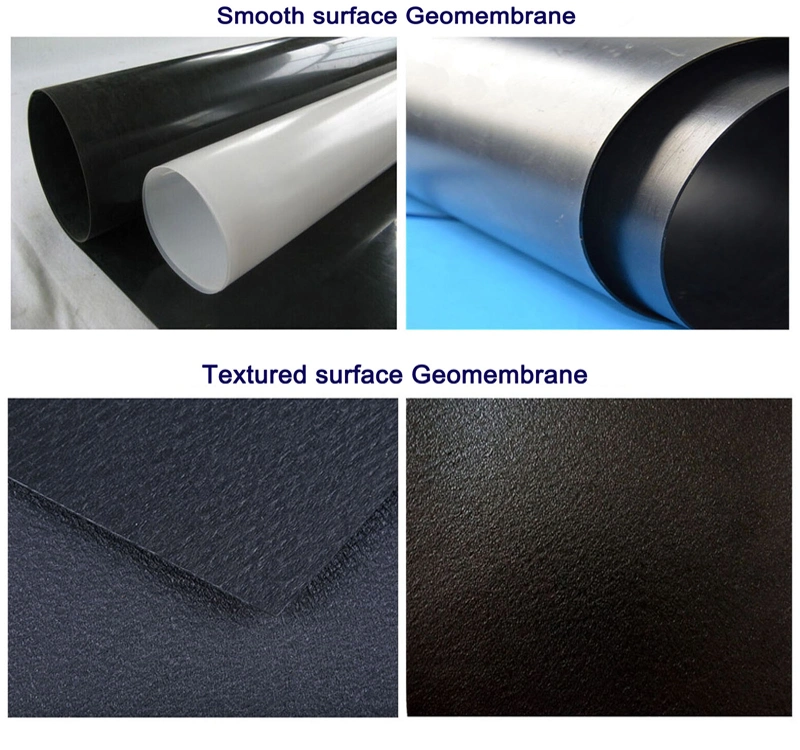

4. Main Color: black, white, blue, green

5. Optional surface: Textured or Smooth surface.

6. Material: HDPE, LDPE,LLDPE,EVA

7. Certificate & Test: ISO, TRI, SGS

8. Quality Control: Third party test and factory lab test

HDPE Geomembrane pond liner TechnicalParameter

ASTM Standard geomembrane

Spec

Properties |

Test method

ASTM |

GMS0.5 |

GMS0.75 |

GMS1.0 |

GMS1.25 |

GMS1.5 |

GMS2.0 |

GMS2.5 |

| Thickness |

D5199 |

0.5mm |

0.75mm |

1.00mm |

1.25mm |

1.50mm |

2.00mm |

2.50mm |

| Density (≥ g/cc) |

D1505 |

0.940 |

0.940 |

0.940 |

0.940 |

0.940 |

0.940 |

0.940 |

Tensile Properties

(Each direction) (≥)

• yield strength

• break strength

• yield elongation

• break elongation |

D 6693

Type IV |

8 kN/m

14kN/m

12%

700% |

11 kN/m

20kN/m

12%

700% |

15 kN/m

27 kN/m

12%

700% |

18 kN/m

33 kN/m

12%

700% |

22 kN/m

40 kN/m

12%

700% |

29 kN/m

53 kN/m

12%

700% |

37kN/m

67kN/m

12%

700% |

| Tear Resistance (≥) |

D 1004 |

64 N |

93 N |

125 N |

156 N |

187 N |

249 N |

311 N |

| Puncture Resistance (≥) |

D 4833 |

160 N |

240 N |

320 N |

400 N |

480 N |

640 N |

800 N |

| Stress Crack Resistance (≥) |

D 5397 |

300 hr. |

300 hr. |

300 hr. |

300 hr. |

300 hr. |

300 hr. |

300 hr. |

| Carbon Black Content |

D 1603 |

2.0-3.0% |

2.0-3.0% |

2.0-3.0% |

2.0-3.0% |

2.0-3.0% |

2.0-3.0% |

2.0-3.0% |

| Carbon Black Dispersion |

D 5596 |

Note(1) |

Note(1) |

Note(1) |

Note(1) |

Note(1) |

Note(1) |

Note(1) |

Oxidative Induction Time (OIT) (≥)

(a)Standard OIT

- or -

(b)High Pressure OIT |

D 3895

D 5885 |

100 min.

400 min. |

100 min.

400 min. |

100 min.

400 min. |

100 min.

400 min. |

100 min.

400 min. |

100 min.

400 min. |

100 min.

400 min. |

Geomembrane liner are made from polyethylene polymer materials by the film-blowing process. it is most widely used for fish pond,solid waste containment (such as landfill liners),mining and water containment applications.

Product Application:

Environmental protection projects:

Landfill,sewage treatment plants,power plant regulating pools,industrial and hospital solid wastes,etc.

Aquaculture projects:

fish ponds,shrimp ponds,industrialized aquaculture ponds,etc.

Agriculture:

Seepage control of reservoirs,reservoirs, irrigation systems,channel etc.

Mining:

heap leaching platforms,conduit and retention channels and wells for liquid solutions,final disposal reservoirs.

Blue and green geomembrane

Packing and Shipping

1. Packing:

PP woven geotextile bags or PE film. Or according to customers requirements.

2. Delivery:

Within 7-10 days after receiving your deposit.

Samples are for your review.

HDPE Geomembrane Application:

HDPE Geomembrane Application:

(1) Aquaculture:

Using the geomembrane anti-seepage feature; geomembrane liners can be used as fish ponds, shrimp pond, tank liner and others.

(2) Landfill:

HDPE geomembrane is the most widely used in landfill anti-seepage engineering material. The use of main parts of the bottom of the landfill liner, landfill sealing cover, leachate regulating pool liner, etc.

FAQ

Q: Are you a factory or trading company?

A: We are the professional factory in China.

Q: How can us get some samples?

A: We are honored to offer you samples. if youneed! The little sample cost can be free,the large quantity samples,can be negotiable. The freight cost,the customers' pay.

Q: How does your factory do regarding quality control?

A: Quality is priority. All people always attach great importance to quality controlling from the very beginning to the very end.

Our factory has gained ISO9001; CPI authentication,We are the National High-Tech Enterprise. We have the professional technical personnel team,advanced equipments; Skilled production technology by ten

years.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!

HDPE Geomembrane Application:

HDPE Geomembrane Application: