Product Description:

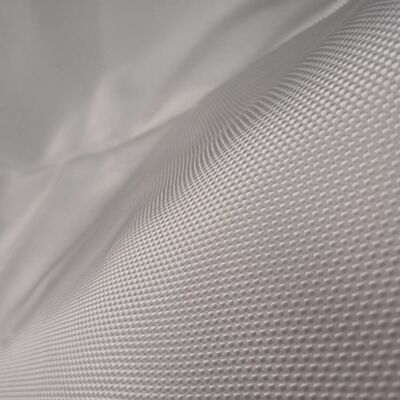

The Woven Geotextile Fabric is a high-performance material designed for a wide range of civil engineering and construction applications. Manufactured from premium quality polyester and polypropylene, this woven geotextile offers exceptional durability, strength, and reliability, making it an ideal choice for soil stabilization, erosion control, drainage, and reinforcement projects. With its carefully engineered properties, this fabric ensures long-lasting performance even under the most demanding conditions.

One of the standout features of this woven geotextile fabric is its versatile aperture size, which ranges from 0.05mm to 0.2mm. This precise aperture size allows for optimal filtration and separation, effectively preventing soil particles from passing through while allowing water to flow freely. This characteristic is crucial in applications where controlling soil movement and maintaining proper drainage are essential for structural integrity and environmental protection.

The fabric is available in lengths ranging from 50 meters to 100 meters, providing flexibility to accommodate projects of various scales. Whether you are working on a small landscaping project or a large-scale infrastructure development, the availability of different length options ensures that you can select the most appropriate size to minimize waste and improve efficiency. Additionally, the width of the fabric is standardized at 5.2 meters, which is ideal for covering large areas quickly and reducing the number of seams required during installation.

Durability and strength are critical factors in selecting a geotextile fabric, and this product excels in these aspects with a tensile strength range of 50KN/m to an impressive 1200KN/m. This high tensile strength ensures that the fabric can withstand significant loads and stresses without tearing or deforming, making it suitable for use in heavy-duty applications such as road construction, retaining walls, and embankments. The robust tensile strength also contributes to the overall longevity of the fabric, reducing the need for frequent replacements and maintenance.

Another significant advantage of this woven geotextile fabric is its ability to minimize construction and installation losses. Thanks to its precise manufacturing and consistent quality, the fabric experiences low construction and installation losses, helping contractors save time and resources during project execution. This efficiency not only reduces overall project costs but also enhances the sustainability of construction practices by minimizing material waste.

The combination of polyester and polypropylene materials provides excellent resistance to environmental factors such as UV radiation, chemical exposure, and microbial degradation. This resistance extends the life span of the fabric, ensuring that it continues to perform effectively throughout the lifecycle of the project. Additionally, the woven structure enhances dimensional stability, preventing elongation and maintaining the fabric's shape under load.

In summary, the Woven Geotextile Fabric is a superior choice for engineers, contractors, and builders seeking a reliable, efficient, and cost-effective solution for soil reinforcement, filtration, and separation. Its customizable aperture sizes, wide width, and length options, along with outstanding tensile strength and durability, make it adaptable to a wide range of applications. Moreover, the fabric’s low construction and installation losses contribute to smoother project workflows and reduced environmental impact. By selecting this woven geotextile fabric, you are investing in a product that delivers high performance and long-term value for your construction and engineering needs.

Features:

- Product Name: Woven Geotextile Fabric

- Length: 50m-100m

- Width: 5.2m

- Color Options: White, Black

- Material: Durable Polyester/Polypropylene

- High CBR Puncture Strength: ≥12KN for enhanced durability

- Ideal for Reinforcement of Roadbed applications

- Effective Soft Ground Treatment solution

- Designed for Low Construction and Installation Losses

Technical Parameters:

| Tensile Strength |

50KN/m - 1200KN/m |

| CBR Puncture Strength |

≥12KN |

| Length |

50m - 100m |

| Width |

5.2m |

| Aperture Size |

0.05 - 0.2mm |

| Elongation |

10% |

| Material |

Polyester / Polypropylene (PET/PP) |

| Color |

White, Black |

Applications:

The HAISAN woven geotextile fabric, originating from CN, is a versatile and durable solution designed for various construction and engineering applications. Available in lengths ranging from 50m to 100m and a width of 5.2m, this product offers exceptional performance with tensile strength between 50KN/m and 1200KN/m and an elongation rate of 10%. Its availability in both white and black colors allows for adaptability based on project requirements.

One of the most common application occasions for HAISAN woven geotextile is in the reinforcement of roadbeds. This fabric significantly enhances the stability and load-bearing capacity of road structures by providing an effective separation layer that prevents the mixing of subgrade and aggregate materials. Its high tensile strength ensures long-lasting support under heavy traffic conditions, making it ideal for highways, rural roads, and airport runways.

In addition to roadbed reinforcement, HAISAN woven geotextile is frequently used in erosion control projects. It helps protect slopes, embankments, and riverbanks by stabilizing the soil and preventing displacement caused by water flow or wind. The low construction and installation losses associated with this woven geotextile fabric make it a cost-effective choice, reducing material waste and labor time during deployment.

Drainage and filtration systems also benefit from the use of HAISAN woven geotextile. Its permeability allows water to pass through while retaining soil particles, making it suitable for use in retaining walls, landfills, and drainage trenches. This ensures efficient water management while maintaining soil integrity.

Furthermore, HAISAN woven geotextile fabric is ideal for landscaping and agricultural applications. It can be used for ground stabilization in parks, golf courses, and sports fields, as well as in agricultural fields to control weed growth and improve soil structure. The fabric’s strength and durability ensure it withstands environmental stressors over time.

Overall, the HAISAN woven geotextile fabric offers reliable performance across a wide range of occasions and scenarios. Its combination of high tensile strength, elongation capacity, and low construction and installation losses makes it an essential material for projects requiring soil reinforcement, stabilization, and filtration.

Customization:

At HAISAN, we offer customized woven geotextile fabric solutions tailored to meet your specific project requirements. Our woven geotextile products, made from high-quality PET/PP (polyester/polypropylene) materials, are designed for superior performance in soft ground treatment applications. With a tensile strength ranging from 50KN/m to 1200KN/m and a CBR puncture strength of ≥12KN, our fabrics ensure durability and reliability under demanding conditions.

Customers can choose from a range of aperture sizes between 0.05mm and 0.2mm to optimize filtration and separation functions. Available in classic white and black colors, our woven geotextile fabrics provide excellent UV resistance and longevity.

Manufactured in China (CN) under the trusted HAISAN brand, our product customization services include tailored dimensions, strength specifications, and color options to perfectly suit your engineering and construction needs. Partner with us for high-performance woven geotextile solutions that enhance the stability and longevity of your soft ground treatment projects.

Support and Services:

Our Woven Geotextile Fabric is designed to provide superior soil stabilization, erosion control, and drainage solutions for a wide range of construction and landscaping projects. For technical support, our team of experts is available to assist with product selection, installation guidelines, and troubleshooting to ensure optimal performance.

We offer comprehensive services including site evaluation, custom fabrication, and on-site technical assistance to help you achieve the best results with our woven geotextile fabric. Our support extends through the entire project lifecycle, from initial planning to final inspection.

For installation, it is recommended to follow industry best practices such as proper surface preparation, adequate overlap between fabric sections, and secure anchoring to prevent movement. Our technical documentation provides detailed instructions and recommendations to facilitate correct application and maximize the fabric’s durability and effectiveness.

Should you require additional information or specialized support, our technical service team is ready to provide expert advice and solutions tailored to your specific project needs.

Packing and Shipping:

Product Packaging and Shipping for Woven Geotextile Fabric

The woven geotextile fabric is carefully rolled and wrapped with protective plastic film to prevent damage and contamination during transportation and storage. Each roll is securely packaged with waterproof materials and labeled with product specifications for easy identification.

For bulk orders, the rolls are stacked on wooden pallets and tightly strapped to ensure stability and safety. Customized packaging options are also available upon request to meet specific shipping requirements.

Shipping is conducted via sea, air, or land freight depending on the destination and urgency. Proper handling instructions are provided to carriers to maintain the integrity of the product throughout the shipping process.

We ensure timely delivery and safe arrival of the woven geotextile fabric to our customers worldwide.

FAQ:

Q1: What is the Woven Geotextile Fabric by HAISAN used for?

A1: HAISAN Woven Geotextile Fabric is commonly used for soil stabilization, erosion control, drainage, and separation in construction and landscaping projects.

Q2: Where is the HAISAN Woven Geotextile Fabric manufactured?

A2: The HAISAN Woven Geotextile Fabric is manufactured in China (Place of Origin: CN).

Q3: What materials are used to make HAISAN Woven Geotextile Fabric?

A3: The fabric is made from high-quality polypropylene or polyester fibers woven into a durable and strong textile.

Q4: How does HAISAN Woven Geotextile Fabric perform in drainage applications?

A4: The woven structure of HAISAN Geotextile Fabric allows water to pass through while preventing soil and debris from clogging drainage systems, making it ideal for drainage applications.

Q5: Is the HAISAN Woven Geotextile Fabric UV resistant?

A5: Yes, HAISAN Woven Geotextile Fabric is treated to be UV resistant, ensuring durability and longevity when exposed to sunlight during outdoor use.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!