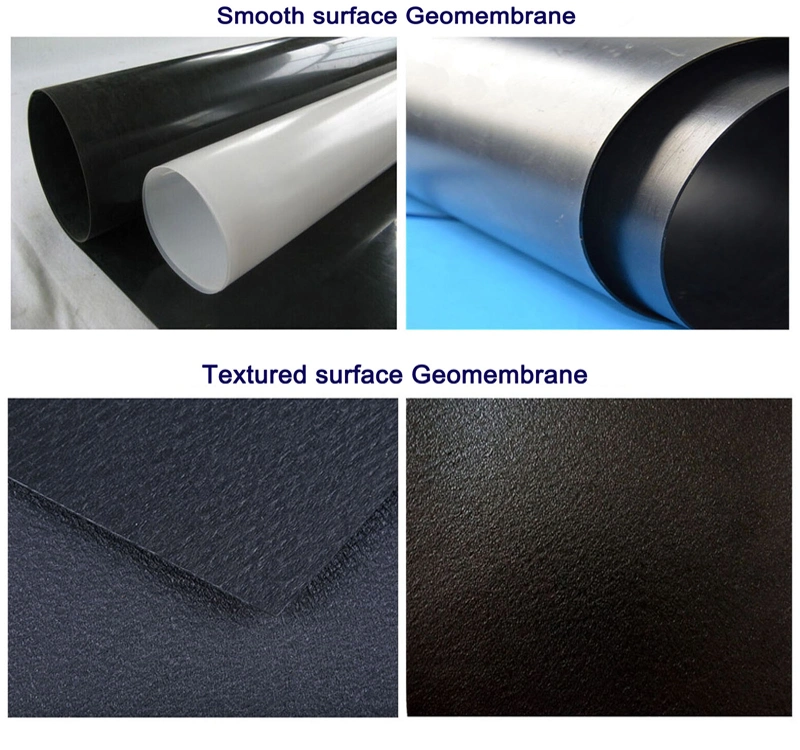

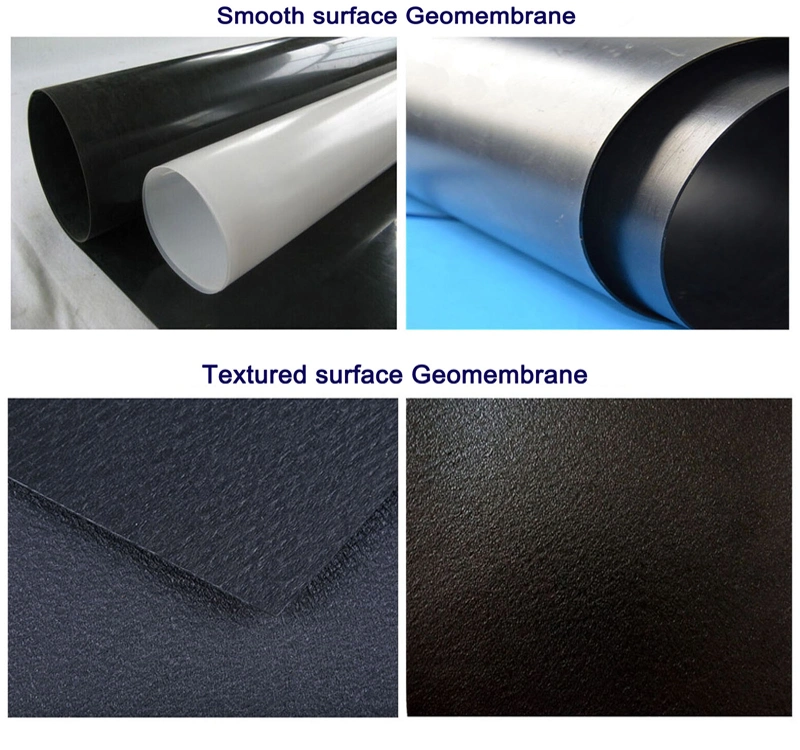

High Quality 1.0mm 2.0mm Water Waterproof Membrane Fish Tank Dam Pond Liner Price HDPE Geomembrane

Product Characters:

1. Environmental friendly formula:

The raw materials we have used meet the international standards, non-toxic, environmentally friendly. It is used for a variety of environmental protection, agriculture and aquaculture waterproof and anti leakage.

2. Aging resistance property:

With excellent anti-aging, anti ultraviolet and anti decomposition ability.

3. High mechanical strength:

Good mechanical strength, there are a variety of specifications to meet the different programs of electrical construction, water conservancy project waterproof.

4. Chemical stability:

Excellent stability, acid and alkali, anti salt solution, oil, alcohol and other 80 kinds of chemical medium corrosion, so it is widely used in sewage treatment, landfill.

5. Puncture resistance:

It has excellent puncture resistance, resist to most of the plant roots, so HDPE geomembrane is roof planting required products.

6. High impervious coefficient:

With perfect waterproof effect that ordinary waterproof materials can not match, it is recommended in some high waterproof requirements of the projects.

7. Fast construction speed:

HDPE geomembrane features high flexibility, with a variety of lay forms to meet the requirements of different projects, convenient and fast construction.

8. Low cost:

It adopts new technology, the production process is more scientific and efficient, so the product cost is lower than the traditional waterproof material. And it is the best product for water storage and seepage control

HDPE Geomembrane pond liner TechnicalParameter

ASTM Standard geomembrane

Spec

Properties |

Test method

ASTM |

GMS0.5 |

GMS0.75 |

GMS1.0 |

GMS1.25 |

GMS1.5 |

GMS2.0 |

GMS2.5 |

| Thickness |

D5199 |

0.5mm |

0.75mm |

1.00mm |

1.25mm |

1.50mm |

2.00mm |

2.50mm |

| Density (≥ g/cc) |

D1505 |

0.940 |

0.940 |

0.940 |

0.940 |

0.940 |

0.940 |

0.940 |

Tensile Properties

(Each direction) (≥)

• yield strength

• break strength

• yield elongation

• break elongation |

D 6693

Type IV |

8 kN/m

14kN/m

12%

700% |

11 kN/m

20kN/m

12%

700% |

15 kN/m

27 kN/m

12%

700% |

18 kN/m

33 kN/m

12%

700% |

22 kN/m

40 kN/m

12%

700% |

29 kN/m

53 kN/m

12%

700% |

37kN/m

67kN/m

12%

700% |

| Tear Resistance (≥) |

D 1004 |

64 N |

93 N |

125 N |

156 N |

187 N |

249 N |

311 N |

| Puncture Resistance (≥) |

D 4833 |

160 N |

240 N |

320 N |

400 N |

480 N |

640 N |

800 N |

| Stress Crack Resistance (≥) |

D 5397 |

300 hr. |

300 hr. |

300 hr. |

300 hr. |

300 hr. |

300 hr. |

300 hr. |

| Carbon Black Content |

D 1603 |

2.0-3.0% |

2.0-3.0% |

2.0-3.0% |

2.0-3.0% |

2.0-3.0% |

2.0-3.0% |

2.0-3.0% |

| Carbon Black Dispersion |

D 5596 |

Note(1) |

Note(1) |

Note(1) |

Note(1) |

Note(1) |

Note(1) |

Note(1) |

Oxidative Induction Time (OIT) (≥)

(a)Standard OIT

- or -

(b)High Pressure OIT |

D 3895

D 5885 |

100 min.

400 min. |

100 min.

400 min. |

100 min.

400 min. |

100 min.

400 min. |

100 min.

400 min. |

100 min.

400 min. |

100 min.

400 min. |

Characteristics:

1. Good flexibility

2. For service temperature range:-70°C~110°C

3. Corrosion resistance, aging resistance

4. Excellent environmental stress cracking resistance property

5. High tensile strength and elongation

Main Features:

1. UV resistance

2. Anti-seepage;

3. Isolation

4. High tearing resistance

5. Puncture-resisting

Blue and green geomembrane

Packing and Shipping

1. Packing:

PP woven geotextile bags or PE film. Or according to customers requirements.

2. Delivery:

Within 7-10 days after receiving your deposit.

Samples are for your review.

FAQ

1. Are you trading company or manufacturer ?

A: We are manufacturer.

2. How long is your lead time ?

A: Generally it is 4-5 days.

3. Do you provide samples ? It's free or extra ?

A: Sure ,we woule like to offer the samples for free change , but pls kindly pay the cost of freight by yourself.

4. IS the size and color can be customized ?

A: Sure , the thickness, width, length and color are customzed , but pls talk the details to our sales before the order.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!