Product Description:

The HDPE Geocell is an innovative and highly effective solution designed to provide exceptional reinforcement and stability in various civil engineering and construction applications. Manufactured by a leading HDPE sheet manufacturer, this Geo Cell Grid product is engineered to deliver superior performance in demanding environments, making it an ideal choice for projects requiring durable and reliable ground stabilization. Whether it is used for road construction, slope protection, or erosion control, this geocell system offers a versatile and reusable solution that addresses multiple challenges faced by engineers and contractors.

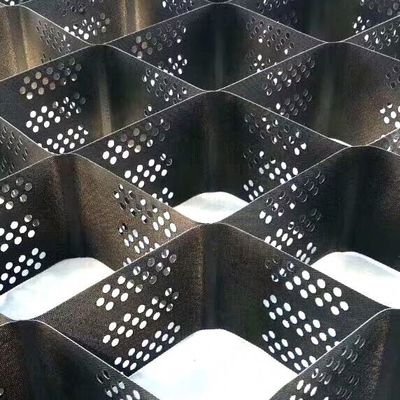

One of the primary functions of the HDPE Geocell is its ability to reinforce soil and other aggregate materials. By confining the fill material within the interconnected cells of the Geo Cell Grid, the product significantly enhances the load-bearing capacity of the underlying soil, preventing displacement and deformation. This reinforcement capability is crucial for applications such as Geocell for road construction, where the stability of the subgrade directly impacts the performance and longevity of the pavement. The geocell’s cellular confinement system distributes loads evenly, reducing rutting and settlement, and thereby extending the lifespan of the road infrastructure.

In addition to reinforcement, the HDPE Geocell is designed to be reusable, offering a sustainable and cost-effective alternative to traditional soil stabilization methods. The product’s robust construction allows it to be dismantled and reinstalled if necessary, which is particularly beneficial for temporary construction projects or areas where future modifications are anticipated. This reusability not only reduces material waste but also contributes to lower overall project costs and environmental impact.

Anti-erosion properties are another significant advantage of the HDPE Geocell. The grid structure effectively controls soil erosion by confining and stabilizing the surface material, preventing displacement caused by water runoff or wind. This makes the product especially valuable in applications such as slope stabilization, riverbank protection, and shoreline reinforcement. The anti-erosion function helps maintain the integrity of the landscape, protecting natural resources and infrastructure from damage.

Durability is a key feature of the HDPE Geocell, as it is manufactured from high-density polyethylene (HDPE), a material known for its excellent resistance to corrosion and chemical attack. This corrosion and chemical-resistant property ensures that the geocell can withstand harsh environmental conditions, including exposure to aggressive soils, chemicals, and ultraviolet radiation. As a result, the product maintains its structural integrity and performance over extended periods, reducing the need for frequent maintenance or replacement.

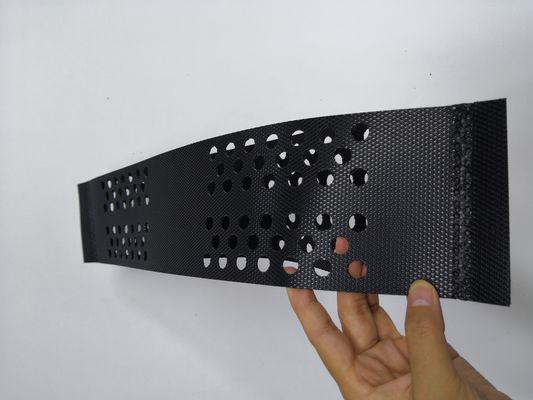

The surface of the HDPE Geocell is designed with a smooth finish, which facilitates easy installation and handling. The smooth surface minimizes friction during deployment, allowing for efficient expansion and anchoring on-site. Additionally, the product is available with different surface textures, including smooth textured or honeycomb type finishes, to cater to various application requirements. These surface options enhance the product’s adaptability and effectiveness in different soil and environmental conditions.

The geocell’s welding space of 330mm is precisely engineered to ensure strong and secure connections between the cells, providing a stable and cohesive grid structure. This welding space dimension is crucial for maintaining the overall integrity of the Geo Cell Grid, ensuring that the cells remain interconnected under load and during environmental stresses. The reliable welding process also contributes to the product’s ease of installation and long-term performance.

In summary, the HDPE Geocell is a high-performance ground reinforcement product that combines strength, durability, and versatility. As a trusted HDPE sheet manufacturer’s offering, it delivers exceptional corrosion and chemical resistance, smooth and textured surface options, and a well-designed welding space of 330mm. Its functions of reinforcement, reusability, and anti-erosion make it an indispensable material for modern construction projects, especially in road construction where stability and longevity are paramount. Choosing this Geo Cell Grid product ensures enhanced soil stabilization, environmental protection, and cost efficiency, making it a smart investment for engineers and contractors alike.

Features:

- Product Name: HDPE Geocell

- Durability: Corrosion and Chemical Resistant

- Applications: Slope Protection, Erosion Control, Load Support

- Function: Reinforce, Reusable, Anti-erosion

- Product Surface: Smooth Textured or Honeycomb Type

- Tensile Strength: ≥ 14.2 KN/m

- Ideal Geocell For Road Construction

- Effective Geo Cell Grid for various civil engineering projects

- Reliable Geocell Ground Grid for soil stabilization

Technical Parameters:

| HDPE Geocell Standard |

ASTM; GB Standard |

| Model Size |

200-356 |

| Thickness |

1.5mm, 1.75mm, 2.0mm |

| Material |

High-Density Polyethylene (HDPE) |

| Tensile Strength |

≥ 14.2 KN/m |

| Durability |

Corrosion And Chemical Resistant |

| Welded Space |

356mm |

| Welding Space |

330mm |

| Function |

Reinforce, Reusable, Anti-erosion |

| Applications |

Slope Protection, Erosion Control, Load Support |

Applications:

The HASSAN HDPE Geocell, model number 150-400, is a versatile and durable solution designed specifically for various engineering and construction applications. Manufactured in China by a reputed HDPE Sheet Manufacturer, this geocell system boasts a smooth textured or honeycomb type surface, providing excellent stability and strength in multiple scenarios. Its unique design includes a welding space of 330mm and a welded space of 356mm, ensuring robust cell formation that enhances load distribution and soil confinement.

One of the primary application occasions for the HASSAN HDPE Geocell is in road construction. As a Geocell for Road Construction, it significantly improves the structural integrity of roads by reinforcing the subgrade and reducing deformation under heavy traffic loads. The product’s corrosion and chemical resistance make it highly suitable for use in harsh environmental conditions, including coastal areas and industrial zones where chemical exposure is common.

Beyond road construction, the HDPE Geocell is ideal for slope protection and erosion control in landscaping and civil engineering projects. Its smooth surface and honeycomb texture facilitate easy installation and provide excellent containment of infill materials such as gravel, sand, or soil. This containment prevents soil erosion on embankments, riverbanks, and retaining walls, thereby enhancing the longevity of these structures.

In addition, the HASSAN HDPE Geocell is widely used in load support applications such as parking lots, railway foundations, and airport runways. The product’s durability and resistance to corrosion and chemicals ensure that it maintains performance over time, even under extreme pressure and environmental stress. This makes it an invaluable asset for infrastructure projects that demand long-lasting and reliable reinforcement solutions.

With its advanced design and superior material properties, the HASSAN HDPE Geocell from a leading HDPE Sheet Manufacturer offers an efficient and cost-effective way to improve ground stability, reduce maintenance costs, and extend the lifespan of various civil engineering structures. Whether used in road construction, erosion control, or load support, this HDPE geocell delivers exceptional performance and durability across a wide range of application scenarios.

Customization:

HASSAN, a leading HDPE Sheet Manufacturer, offers customizable HDPE Geocell products designed to meet diverse engineering needs. Our HDPE Geocell, model number 150-400, is made from high-quality High-Density Polyethylene (HDPE) sourced from CHINA, ensuring durability and superior performance.

Our Geo Cell Grid is engineered to reinforce and stabilize soil structures, making it ideal for Geocell For Road Construction and other erosion control applications. The product features a smooth surface and complies with ASTM and GB Standards, guaranteeing reliable quality and performance.

The HDPE Geocell is reusable and provides excellent anti-erosion properties. It can be filled with various materials such as concrete, soil, and rock, allowing for versatile application in construction and landscaping projects. Trust HASSAN’s HDPE Geocell for effective reinforcement and long-lasting stability in your infrastructure developments.

Support and Services:

Our HDPE Geocell product is designed to provide superior soil stabilization, erosion control, and load support in a variety of civil engineering applications. For technical support, our team of experts is available to assist with product selection, design recommendations, and installation guidelines to ensure optimal performance of the geocell system.

We offer comprehensive services including site assessment, customized engineering solutions, and on-site technical assistance. Our support ensures that the HDPE Geocell product meets the specific requirements of your project, enhancing durability and efficiency.

For installation, we provide detailed manuals and training sessions to help your team correctly deploy the geocell panels, minimizing errors and maximizing effectiveness. Our experts can also conduct post-installation inspections to verify proper application and long-term stability.

Additionally, we supply maintenance advice and troubleshooting assistance to address any issues that may arise during the lifespan of the HDPE Geocell system, ensuring sustained performance and reliability.

We are committed to delivering high-quality support and services to help you achieve successful project outcomes with our HDPE Geocell products.

Packing and Shipping:

The HDPE Geocell product is carefully packaged to ensure maximum protection during transportation and handling. Each geocell panel is folded compactly and secured with durable straps to maintain its shape and prevent damage. The packaged geocells are then placed in sturdy, weather-resistant plastic wrapping to safeguard against moisture, dust, and other environmental factors.

For shipping, the packaged HDPE Geocells are loaded onto pallets and wrapped with stretch film to provide additional stability. The pallets are clearly labeled with product information, handling instructions, and destination details to facilitate smooth logistics. Depending on order size and destination, shipments can be sent via truck, container, or freight services, ensuring timely and safe delivery to the customer’s site.

FAQ:

Q1: What is the HASSAN HDPE Geocell Model 150-400 used for?

A1: The HASSAN HDPE Geocell Model 150-400 is primarily used for soil stabilization, erosion control, and load support in construction projects such as roadways, slopes, and retaining walls.

Q2: Where is the HASSAN HDPE Geocell manufactured?

A2: The HASSAN HDPE Geocell Model 150-400 is manufactured in China, ensuring high-quality production standards.

Q3: What material is the HASSAN HDPE Geocell made from?

A3: The geocell is made from high-density polyethylene (HDPE), which provides excellent durability, flexibility, and resistance to chemicals and UV exposure.

Q4: What are the dimensions and specifications of the HASSAN HDPE Geocell Model 150-400?

A4: The model number 150-400 indicates the cell size and thickness range, with the cells typically measuring 150 mm in width and the material thickness ranging up to 400 microns, suitable for various load-bearing applications.

Q5: How is the HASSAN HDPE Geocell installed on site?

A5: Installation involves expanding the geocell panels on the prepared ground surface, anchoring them in place, and then filling the cells with soil, gravel, or concrete to create a stable and reinforced structure.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!