Product Description:

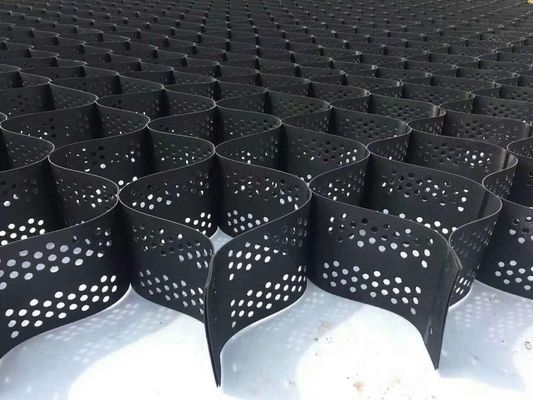

The HDPE Geocell is an advanced geosynthetic product designed to provide superior ground stabilization and reinforcement for a wide range of civil engineering and landscaping applications. Manufactured from high-density polyethylene (HDPE), this geocell system offers exceptional strength, durability, and environmental resistance, making it an ideal solution for projects requiring long-lasting soil confinement and erosion control. The product is available in two types of surface textures – smooth textured and honeycomb type – allowing for versatile application depending on the project requirements and site conditions.

One of the key features of this HDPE Geocell is its welded space of 356mm, which ensures a consistent and reliable grid structure that can effectively distribute loads and reinforce the soil. This welded spacing provides an optimal balance between flexibility and rigidity, enabling the geocell ground grid to conform to uneven terrain while maintaining structural integrity. The uniform cell size also facilitates easy installation and integration with other ground stabilization materials, enhancing overall project efficiency.

The HDPE Geocell complies with stringent international standards such as ASTM and ISO, ensuring that the product meets high-quality benchmarks for material performance, durability, and environmental safety. These standards guarantee that the geocell grid will perform reliably under various environmental conditions, including exposure to UV radiation, moisture, and temperature fluctuations. Additionally, the inclusion of 1.5% carbon black in the geocell material enhances its UV resistance and extends its service life by protecting it from degradation caused by prolonged sun exposure.

With a smooth surface finish, the HDPE Playground variant of this geocell product provides an excellent option for recreational areas where safety and aesthetics are paramount. The smooth surface reduces the risk of abrasions and injuries, making it suitable for playgrounds and other public spaces. Furthermore, the geocell ground grid structure ensures effective load distribution, reducing soil displacement and surface rutting caused by heavy foot traffic and playground equipment.

In addition to playground applications, the Geo Cell Grid is widely utilized in slope protection, retaining wall reinforcement, road base stabilization, and erosion control projects. Its three-dimensional honeycomb configuration confines the infill material, such as soil, gravel, or sand, preventing lateral movement and significantly improving load-bearing capacity. This makes the HDPE Geocell an indispensable component in infrastructure projects that demand enhanced ground stability and sustainability.

Installation of the HDPE Geocell is straightforward and efficient due to its lightweight and flexible design. The welded 356mm spacing allows the grid to be expanded and anchored securely on-site, accommodating various terrain shapes and slopes. This adaptability reduces construction time and labor costs while delivering superior performance compared to traditional soil reinforcement methods.

Environmental sustainability is also a core advantage of the HDPE Geocell. By stabilizing soil and controlling erosion, it helps to preserve natural landscapes and prevent sediment runoff into waterways. Its durable HDPE composition ensures a long service life, reducing the need for frequent repairs or replacements and minimizing resource consumption over the life cycle of a project.

In summary, the HDPE Geocell with smooth textured or honeycomb type surfaces, 356mm welded spacing, and compliance with ASTM and ISO standards represents a high-performance solution for ground stabilization and reinforcement. The product’s smooth surface and 1.5% carbon black content enhance durability and UV resistance, making it suitable for diverse applications including HDPE playground installations and civil infrastructure projects. Whether used as a geocell ground grid or Geo Cell Grid, this product delivers reliable performance, ease of installation, and environmental benefits, making it a preferred choice among engineers, contractors, and landscape architects worldwide.

Features:

- Product Name: HDPE Geocell

- Welded Space: 356mm

- Welding Space: 330mm

- Standard Compliance: ASTM, ISO

- Durability: Corrosion and Chemical Resistant

- Applications: Slope Protection, Erosion Control, Load Support

- Ideal for use as a Geocell Ground Grid

- Suitable for HDPE Playground installations

- Reliable Geocell Ground Grid for various engineering projects

Technical Parameters:

| Tensile Strength |

≥ 14.2 KN/m |

| Durability |

Corrosion And Chemical Resistant |

| HDPE Geocell Standard |

ASTM; GB Standard |

| Surface |

Smooth |

| Model Size |

200-356 |

| Function |

Reinforce, Reusable, Anti-erosion |

| Filler |

Concrete Materials, Soil & Rock |

| Product Surface |

Smooth Textured Or Honeycomb Type |

| Material |

High-Density Polyethylene (HDPE) |

| Standard Compliance |

ASTM, ISO |

Applications:

The HASSAN HDPE Geocell, model number 150-400, originating from China, is a high-quality geocell ground grid designed to meet rigorous standards such as ASTM and GB Standard. This versatile geo cell grid is engineered to provide excellent reinforcement, making it an ideal solution for various civil engineering and construction applications. With a welding space of 330mm, the HASSAN geocell ensures robust structural integrity and durability, suitable for demanding environments.

One of the primary application occasions for the HASSAN HDPE Geocell is slope protection. Slopes prone to erosion and landslides can be effectively stabilized using this geocell ground grid. Its anti-erosion function helps to hold soil in place, preventing washouts during heavy rains or floods. This makes it particularly valuable in hillside construction, riverbanks, and embankment stabilization projects where soil retention is critical for safety and sustainability.

In addition to slope protection, the HASSAN geocell is widely used for erosion control in various landscapes. The interconnected honeycomb structure of the geo cell grid distributes loads evenly, minimizing soil displacement and surface runoff. This makes it an excellent choice for protecting shorelines, drainage channels, and reclaimed land areas. The reusable nature of the HDPE material also allows for cost-effective and environmentally friendly erosion management solutions over time.

Load support is another significant application scenario for the HASSAN HDPE Geocell. It is extensively used in geocell for road construction projects to reinforce subgrade layers, improve load distribution, and enhance overall pavement performance. By stabilizing weak soils and reducing rutting and settlement, the geocell ground grid ensures longer-lasting roads with reduced maintenance costs. This makes it highly suitable for highways, rural roads, parking lots, and heavy-duty industrial pavements.

Overall, the HASSAN HDPE Geocell model 150-400 combines compliance with ASTM, ISO, and GB standards with its multifunctional features of reinforcement, reusability, and anti-erosion capabilities. Its adaptability across slope protection, erosion control, and load support applications makes it an indispensable product for modern infrastructure and environmental protection projects.

Customization:

HASSAN offers customized HDPE Geocell products with model numbers ranging from 150 to 400, manufactured in CHINA. Our Geocell Ground Grid solutions are designed to meet various project requirements, featuring thickness options of 1.5mm, 1.75mm, and 2.0mm to ensure optimal performance and durability.

Our HDPE Playground and Geocell Ground Grid products comply with ASTM and ISO standards, guaranteeing high quality and reliability. The smooth surface of the geocells enhances ease of installation and effective bonding with filler materials such as concrete, soil, and rock.

With a tensile strength of ≥ 14.2 KN/m, HASSAN’s HDPE Geocell Ground Grid is ideal for reinforcing and stabilizing terrain in playgrounds, landscaping, and civil engineering projects. We provide tailored customization services to meet your specific thickness, size, and material requirements for superior ground stabilization solutions.

Support and Services:

Our HDPE Geocell product is designed to provide superior soil stabilization, erosion control, and load support for a wide range of civil engineering and construction applications. Manufactured from high-quality high-density polyethylene, the geocell offers excellent durability, flexibility, and resistance to environmental factors such as UV radiation, chemicals, and extreme temperatures.

For technical support, our team of experts is available to assist with product selection, design recommendations, and installation guidelines to ensure optimal performance of the HDPE Geocell in your specific project conditions. We provide detailed technical documentation, including design manuals, installation instructions, and case studies to support your engineering needs.

Our services also include on-site technical assistance and training sessions to help contractors and engineers understand the best practices for handling and deploying the geocell system. We aim to help you achieve maximum efficiency and longevity from the product.

In addition, we offer customized solutions tailored to unique project requirements, including different cell sizes, thicknesses, and materials to meet specific load-bearing and environmental challenges.

We are committed to ensuring customer satisfaction through continuous support throughout the project lifecycle, from initial consultation to post-installation follow-up. Our goal is to provide reliable, high-performance geocell solutions that contribute to sustainable and cost-effective infrastructure development.

Packing and Shipping:

Product Packaging:

The HDPE Geocell is carefully folded and wrapped in protective plastic film to prevent damage during handling and transportation. It is then packed into sturdy wooden crates or heavy-duty cardboard boxes, depending on the order size and customer requirements. Each package is clearly labeled with product specifications, batch number, and handling instructions to ensure proper identification and care.

Shipping:

HDPE Geocell products are shipped using reliable freight carriers that specialize in handling industrial materials. The packaging is designed to withstand stacking and rough handling during transit. For international shipments, all necessary export documentation and customs clearance paperwork are prepared to facilitate smooth delivery. Depending on the destination and volume, shipping options include sea freight, air freight, or road transport, ensuring timely and secure delivery to the customer’s site.

FAQ:

Q1: What is the HASSAN HDPE Geocell model 150-400 used for?

A1: The HASSAN HDPE Geocell model 150-400 is primarily used for soil stabilization, erosion control, slope protection, and load support in construction and landscaping projects.

Q2: Where is the HASSAN HDPE Geocell manufactured?

A2: The HASSAN HDPE Geocell model 150-400 is manufactured in China.

Q3: What material is the HASSAN HDPE Geocell made of?

A3: The HASSAN HDPE Geocell is made from high-density polyethylene (HDPE), which provides excellent durability, flexibility, and resistance to chemicals and UV radiation.

Q4: What are the typical dimensions or specifications of the HASSAN HDPE Geocell 150-400?

A4: The model number 150-400 refers to the cell size and height dimensions, where 150 mm is the cell width and 400 mm is the cell height, suitable for various ground reinforcement applications.

Q5: Can the HASSAN HDPE Geocell be used in harsh environmental conditions?

A5: Yes, the HASSAN HDPE Geocell is designed to withstand harsh environmental conditions including extreme temperatures, UV exposure, and chemical contact, making it ideal for long-term outdoor use.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!