Product Description:

The HDPE Geocell is a highly durable and versatile product designed to provide exceptional support and reinforcement in various civil engineering and construction applications. Manufactured by a reputable HDPE Sheet Manufacturer, this geocell is crafted from high-quality high-density polyethylene (HDPE) material, ensuring superior strength and longevity. One of the notable features of this HDPE Geocell is the incorporation of 1.5% carbon black, which significantly enhances its resistance to ultraviolet (UV) degradation, thereby extending the product's lifespan even under harsh environmental conditions.

Durability is a critical factor in the performance of geocells, and our HDPE Geocell excels in this aspect. It is corrosion and chemical resistant, making it ideal for use in challenging environments where exposure to aggressive chemicals or corrosive substances is common. This resistance ensures that the geocell maintains its structural integrity over time, providing reliable reinforcement for soil stabilization and erosion control projects.

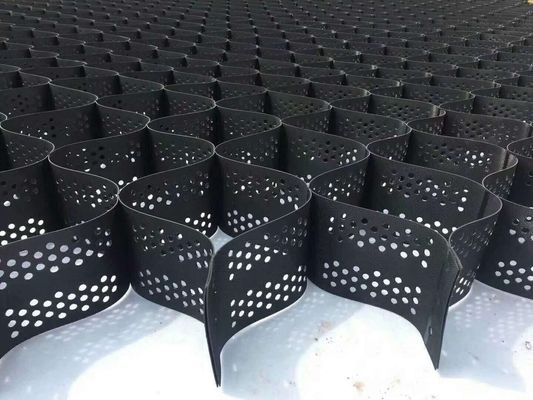

The HDPE Geocell is designed with a welding space of 330mm, which allows for efficient and secure joining of the cell walls. This precise welding spacing contributes to the overall stability and load-bearing capacity of the geocell structure. The cells can be filled with a variety of materials such as concrete, soil, or rock, depending on the specific requirements of the project. This flexibility in filler materials makes the HDPE Geocell an excellent choice for different applications, including slope protection, retaining walls, and foundation reinforcement.

Our HDPE Geocell complies with both ASTM and GB standards, ensuring that it meets stringent quality and performance criteria recognized internationally. Adherence to these standards guarantees that the product will perform reliably in demanding construction scenarios, providing engineers and contractors with confidence in its capabilities. The combination of ASTM and GB standard compliance also reflects the product's versatility and acceptance in global markets.

One of the primary applications of this HDPE Geocell is in road construction. Geocell for road construction is increasingly recognized as an effective solution for improving load distribution, reducing rutting, and enhancing the overall stability of roadbeds. By confining the filler materials within the interconnected cells, the geocell system distributes loads more evenly across the subgrade, minimizing deformation and extending the lifespan of the road. This makes it an indispensable component in modern infrastructure projects aimed at building durable and sustainable roadways.

In summary, the HDPE Geocell from our company stands out as a superior product due to its high carbon black content, exceptional durability, and compliance with international standards. As a leading HDPE Sheet Manufacturer, we ensure that each geocell is produced with precision and quality to meet the rigorous demands of construction professionals. Whether used for road construction, soil stabilization, or erosion control, this HDPE Geocell offers a reliable and cost-effective solution that enhances project performance and longevity. With its corrosion and chemical resistance, standardized specifications, and adaptable filler options, it remains a top choice for engineers seeking dependable geocell products.

Features:

- Product Name: HDPE Geocell

- Material: High-Density Polyethylene (HDPE)

- Welded Space: 356mm

- Geocell Carbon Black Content: 1.5%

- Thickness Options: 1.5mm, 1.75mm, 2.0mm

- Function: Reinforce, Reusable, Anti-erosion

- Ideal for HDPE Playground applications

- Effective Geocell Ground Grid solution for soil stabilization

- Durable and resistant material suitable for HDPE Playground environments

Technical Parameters:

| Standard Compliance |

ASTM, ISO |

| HDPE Geocell Standard |

ASTM; GB Standard |

| Tensile Strength |

≥ 14.2 KN/m |

| Function |

Reinforce, Reusable, Anti-erosion |

| Material |

High-Density Polyethylene (HDPE) |

| Model Size |

200-356 |

| Surface |

Smooth |

| Geocell Carbon Black |

1.5% |

| Durability |

Corrosion And Chemical Resistant |

| Product Surface |

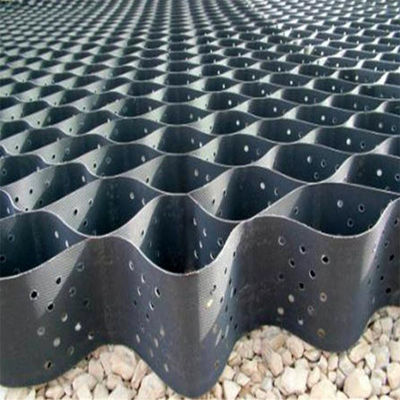

Smooth Textured Or Honeycomb Type |

Applications:

The HASSAN HDPE Geocell, model number 150-400, is an advanced geotechnical product originating from China, designed specifically to enhance ground stability and load distribution in various construction and landscaping projects. Featuring a welded space of 356mm and an alternative welding space of 330mm, this Geocell Ground Grid offers exceptional flexibility and strength. The product size ranges from 200 to 356mm, accommodating diverse site requirements. Its surface is available in either a smooth textured finish or a honeycomb type, ensuring excellent interaction with filler materials such as concrete, soil, and rock.

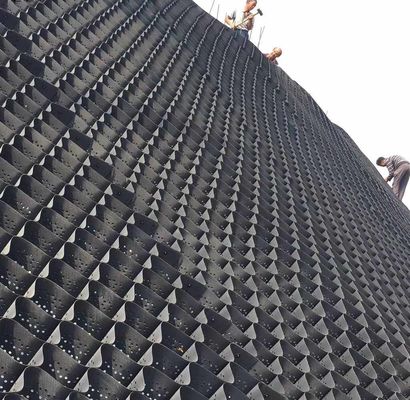

The HASSAN Geo Cell Grid is highly suitable for road construction applications, where ground reinforcement and erosion control are critical. By confining soil and aggregate within its honeycomb structure, it significantly improves load-bearing capacity and prevents lateral displacement. This makes it an ideal solution for building durable road bases, highways, and airport runways, especially in areas with weak or unstable soil conditions. The geocell’s ability to evenly distribute loads reduces rutting and cracking, thereby extending the lifespan of road infrastructure.

Beyond road construction, the HDPE Geocell is widely used in slope stabilization and erosion control projects. Its modular and lightweight design allows easy installation on embankments, riverbanks, and retaining walls, where it secures soil and prevents washouts caused by heavy rainfall or flooding. The product’s compatibility with various filler materials such as soil, concrete, and rocks enhances its adaptability to different environmental conditions and project specifications.

Moreover, the HASSAN Geocell Ground Grid is utilized in landscaping and green infrastructure developments to create sustainable and resilient surfaces. It supports vegetation growth while stabilizing the underlying ground, making it perfect for green roofs, sports fields, and pedestrian pathways. The smooth textured or honeycomb surface options provide versatility in design and functionality, catering to aesthetic and structural needs alike.

In summary, the HASSAN HDPE Geocell model 150-400 is a reliable and versatile geocell solution for a wide range of applications including road construction, slope protection, erosion control, and landscaping. Its robust welded structure, adaptable size, and compatibility with various fillers make it an indispensable tool for engineers and contractors seeking to enhance ground performance and sustainability.

Customization:

HASSAN offers customizable HDPE Geocell products, model number 150-400, designed specifically for applications such as slope protection, erosion control, and load support. Manufactured in China, these geocells provide excellent durability and performance for various engineering projects.

The model size ranges from 200 to 356 mm, with a welded space of 356 mm, ensuring optimal structural integrity and flexibility. With a carbon black content of 1.5%, the geocells are highly resistant to UV degradation and environmental factors.

Featuring a tensile strength of ≥ 14.2 KN/m, HASSAN’s HDPE Geocell is ideal for Geocell For Road Construction and serves effectively as a Geocell Ground Grid for stabilizing soil and improving load distribution. Customize your geocell dimensions and specifications to perfectly suit your project requirements.

Support and Services:

Our HDPE Geocell products are designed to provide exceptional soil stabilization and erosion control solutions for a variety of civil engineering applications. To ensure optimal performance and longevity of the geocell system, we offer comprehensive technical support and services.

Our technical support team is available to assist with project design, installation guidance, and troubleshooting. We provide detailed design recommendations based on site-specific conditions, including load requirements, soil type, and environmental factors. Our experts can help you select the appropriate geocell dimensions and specifications to meet your project needs.

Installation support includes step-by-step instructions, best practices, and on-site assistance if required. We advise on proper surface preparation, panel expansion, anchoring methods, and infill material selection to guarantee effective confinement and structural stability.

Additionally, we offer training sessions and workshops for contractors and engineers to ensure proper handling and installation of HDPE Geocell systems. Our commitment to quality and customer satisfaction means we are always ready to provide ongoing support throughout the project lifecycle.

For any technical inquiries or service requests related to HDPE Geocell products, please reach out to our dedicated support team who will be happy to assist you.

Packing and Shipping:

Product Packaging and Shipping for HDPE Geocell

The HDPE Geocell panels are carefully folded and bundled to ensure minimal space usage and protection during transit. Each bundle is securely wrapped with stretch film and reinforced with straps to prevent movement and damage.

Packaging is designed to withstand various weather conditions and handling during shipping, ensuring that the product arrives in excellent condition.

For shipping, the HDPE Geocell bundles are loaded onto pallets or containers depending on the order size. Standard shipping methods include sea freight, air freight, and road transport, with appropriate documentation provided for customs clearance.

Special handling instructions are included for oversized or bulk orders to guarantee safe and timely delivery to the customer’s site.

FAQ:

Q1: What is the HASSAN HDPE Geocell Model 150-400 made of?

A1: The HASSAN HDPE Geocell Model 150-400 is made of high-density polyethylene (HDPE), which provides excellent durability, flexibility, and resistance to chemicals and UV radiation.

Q2: Where is the HASSAN HDPE Geocell manufactured?

A2: The HASSAN HDPE Geocell Model 150-400 is manufactured in China, ensuring high-quality production standards.

Q3: What are the typical applications of the HASSAN HDPE Geocell 150-400?

A3: The HASSAN HDPE Geocell 150-400 is commonly used for soil stabilization, erosion control, load support, slope protection, and retaining wall reinforcement.

Q4: What are the dimensions of the HASSAN HDPE Geocell Model 150-400?

A4: The model number 150-400 indicates the cellular size and thickness, where 150 mm is the cell height and 400 mm is the cell width, designed to provide optimal strength and flexibility.

Q5: How does the HDPE material benefit the performance of the HASSAN Geocell?

A5: HDPE material offers excellent resistance to UV rays, chemicals, and environmental degradation, which ensures long-term durability and effectiveness of the HASSAN Geocell in various environmental conditions.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!