0.2 - 3mm LDPE Geomembrane Price Dam Reservoir Mining Fish Farm Pond LinerHot Sale Products

Product Description:

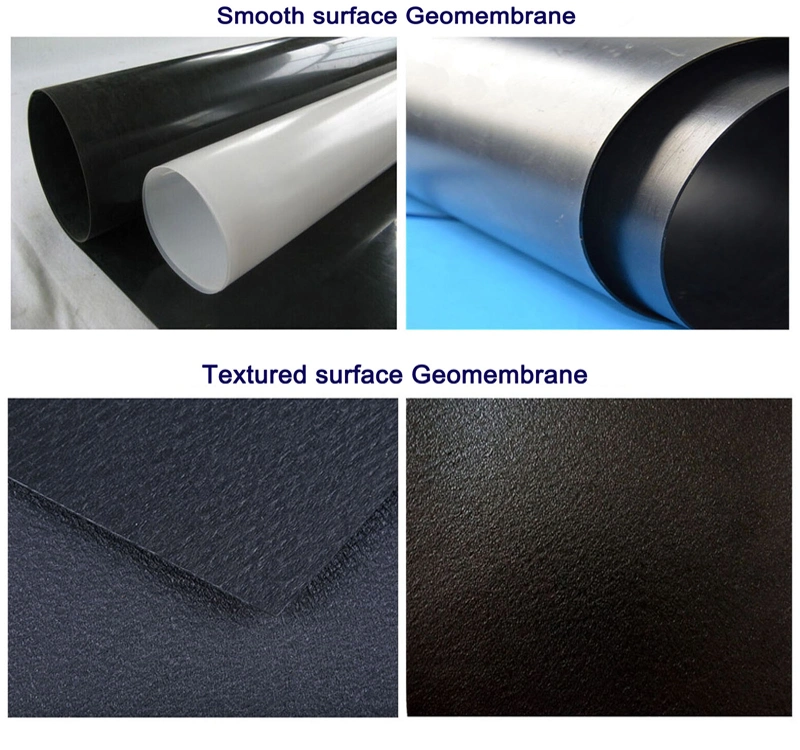

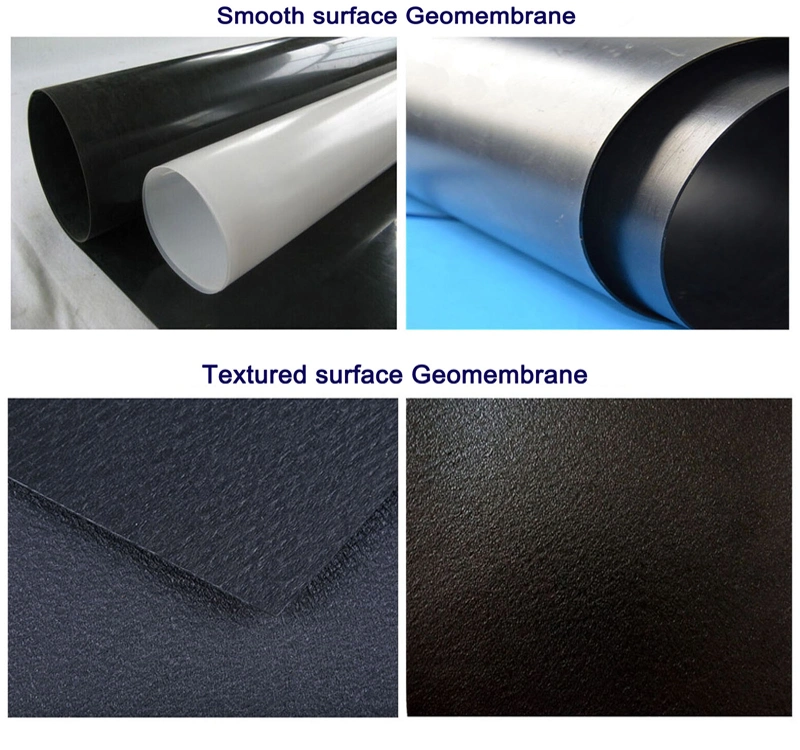

Geomembrane is very low permeability synthetic membrane liner or barrier used with any geotechnical engineering related material so as to control fluid (or gas) migration in a human-made project, structure, or system.

Geomembranes are made from relatively thin continuous polymeric sheets, but they can also be made from the impregnation of geotextiles with asphalt, elastomer or polymer sprays, or as multilayered bitumen geocomposites.

Continuous polymer sheet geomembranes are, by far, the most common.

Application:

1. As waterproofing liners within tunnels and pipelines.

2. As liners for reserve water.

3. As liners for radioactive or hazardous waste liquid.

4. As liners for solar ponds.

5. As liners for the agriculture industry.

6. As liners for water conveyance canals.

7. As liners for all decorative and architectural ponds.

8. As covers (caps) for solid-waste landfills.

9. As liners for heap leach pads.

10. As covers for power plant coal ash.

11. As linings for emergency spillways.

12. As waterproof facing of earth and rockfill dams.

Blue and green geomembrane

LDPE Geomembrane pond liner TechnicalParameter

ASTM Standard geomembrane

Spec

Properties |

Test method

ASTM |

GMS0.5 |

GMS0.75 |

GMS1.0 |

GMS1.25 |

GMS1.5 |

GMS2.0 |

GMS2.5 |

| Thickness |

D5199 |

0.5mm |

0.75mm |

1.00mm |

1.25mm |

1.50mm |

2.00mm |

2.50mm |

| Density (≥ g/cc) |

D1505 |

0.940 |

0.940 |

0.940 |

0.940 |

0.940 |

0.940 |

0.940 |

Tensile Properties

(Each direction) (≥)

• yield strength

• break strength

• yield elongation

• break elongation |

D 6693

Type IV |

8 kN/m

14kN/m

12%

700% |

11 kN/m

20kN/m

12%

700% |

15 kN/m

27 kN/m

12%

700% |

18 kN/m

33 kN/m

12%

700% |

22 kN/m

40 kN/m

12%

700% |

29 kN/m

53 kN/m

12%

700% |

37kN/m

67kN/m

12%

700% |

| Tear Resistance (≥) |

D 1004 |

64 N |

93 N |

125 N |

156 N |

187 N |

249 N |

311 N |

| Puncture Resistance (≥) |

D 4833 |

160 N |

240 N |

320 N |

400 N |

480 N |

640 N |

800 N |

| Stress Crack Resistance (≥) |

D 5397 |

300 hr. |

300 hr. |

300 hr. |

300 hr. |

300 hr. |

300 hr. |

300 hr. |

| Carbon Black Content |

D 1603 |

2.0-3.0% |

2.0-3.0% |

2.0-3.0% |

2.0-3.0% |

2.0-3.0% |

2.0-3.0% |

2.0-3.0% |

| Carbon Black Dispersion |

D 5596 |

Note(1) |

Note(1) |

Note(1) |

Note(1) |

Note(1) |

Note(1) |

Note(1) |

Oxidative Induction Time (OIT) (≥)

(a)Standard OIT

- or -

(b)High Pressure OIT |

D 3895

D 5885 |

100 min.

400 min. |

100 min.

400 min. |

100 min.

400 min. |

100 min.

400 min. |

100 min.

400 min. |

100 min.

400 min. |

100 min.

400 min. |

Packing and Shipping

1. Packing:

PP woven geotextile bags or PE film. Or according to customers requirements.

2. Delivery:

Within 7-10 days after receiving your deposit.

Samples are for your review.

FAQ

1. Are you trading company or manufacturer ?

A: We are manufacturer.

2. How long is your lead time ?

A: Generally it is 4-5 days.

3. Do you provide samples ? It's free or extra ?

A: Sure ,we woule like to offer the samples for free change , but pls kindly pay the cost of freight by yourself.

4. IS the size and color can be customized ?

A: Sure , the thickness, width, length and color are customzed , but pls talk the details to our sales before the order.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!